Can a Fully Automatic High-Temperature Pulsator Washer Improve Cleaning Efficiency and Reduce Water and Energy Consumption?

In recent years, advancements in cleaning technology have led to the development of various automated and high-efficiency washing systems. One such innovation is the fully automatic high-temperature pulsator washer. These machines have gained attention for their potential to improve cleaning efficiency while also reducing water and energy consumption. In industries where cleanliness is paramount, such as food processing, pharmaceuticals, and manufacturing, improving washing processes can significantly enhance overall operational efficiency. In this article, we will explore how fully automatic high-temperature pulsator washers work, the benefits they offer, and how they can help reduce both water and energy usage while improving cleaning performance.

Understanding the Fully Automatic High-Temperature Pulsator Washer

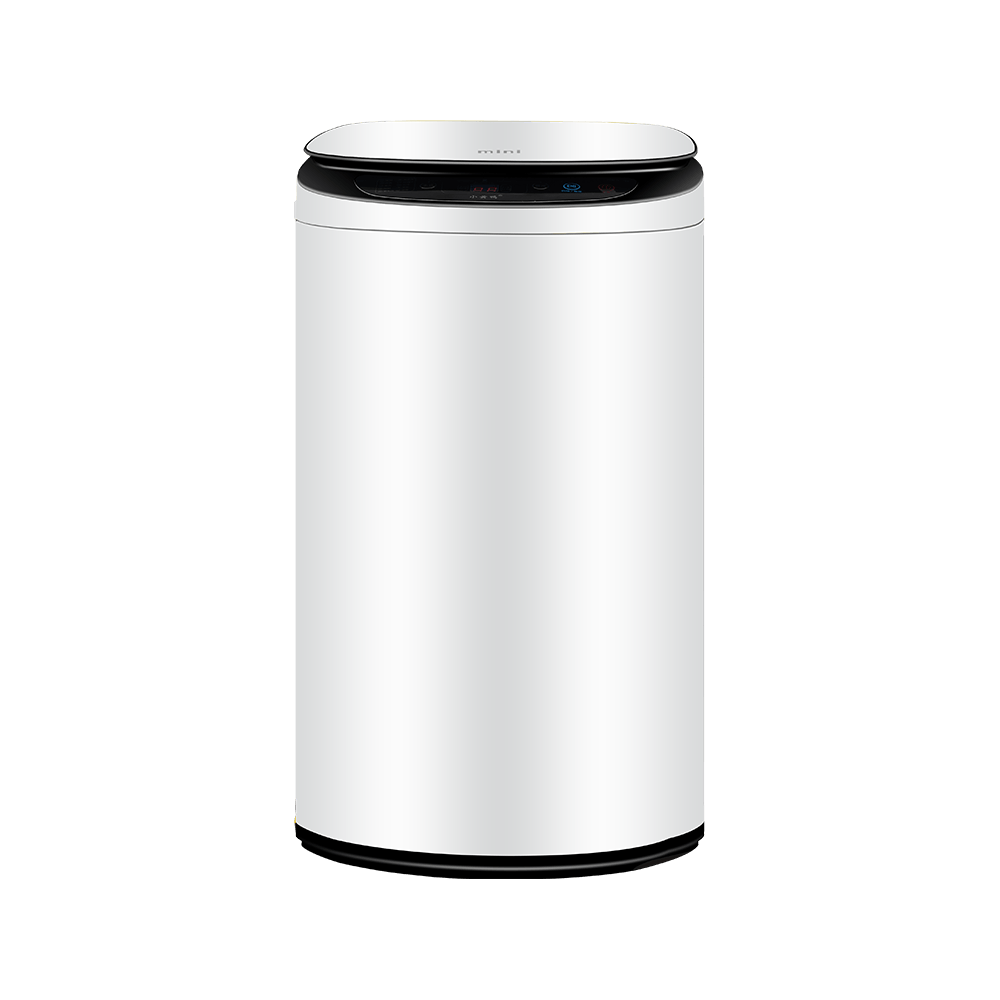

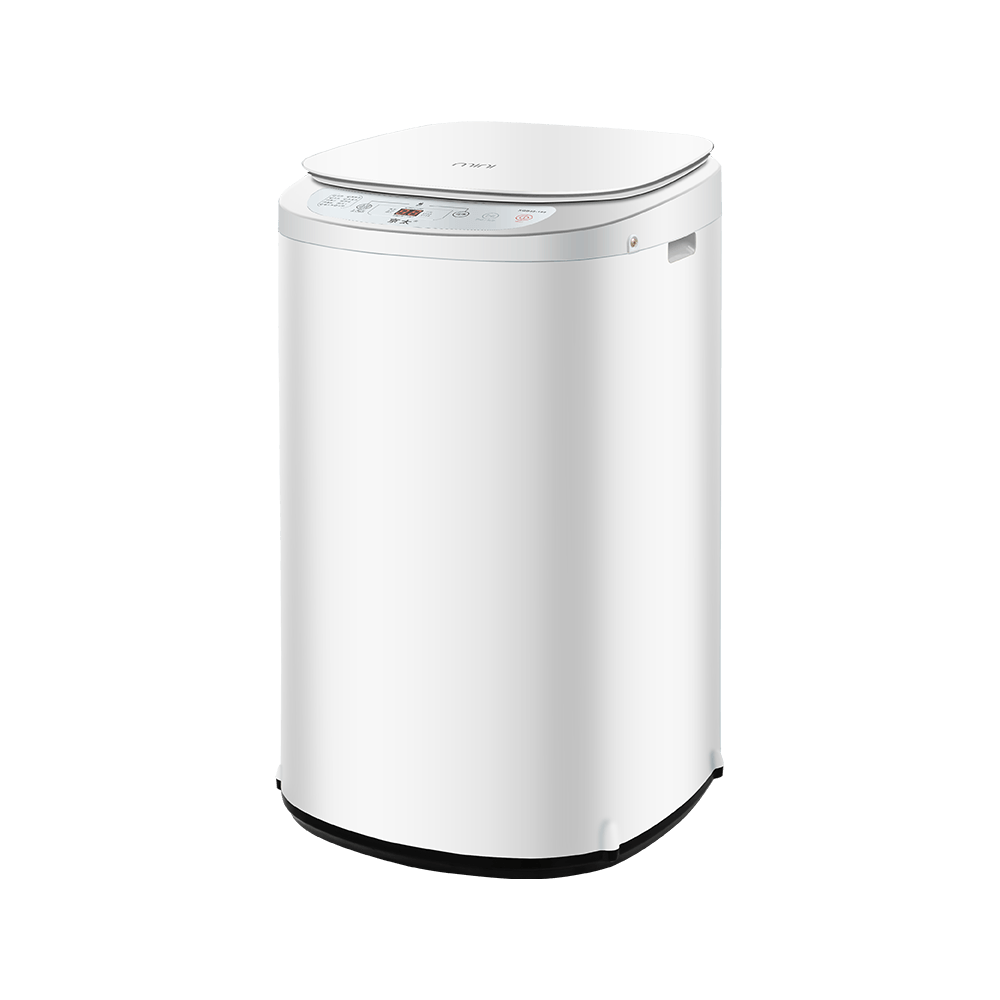

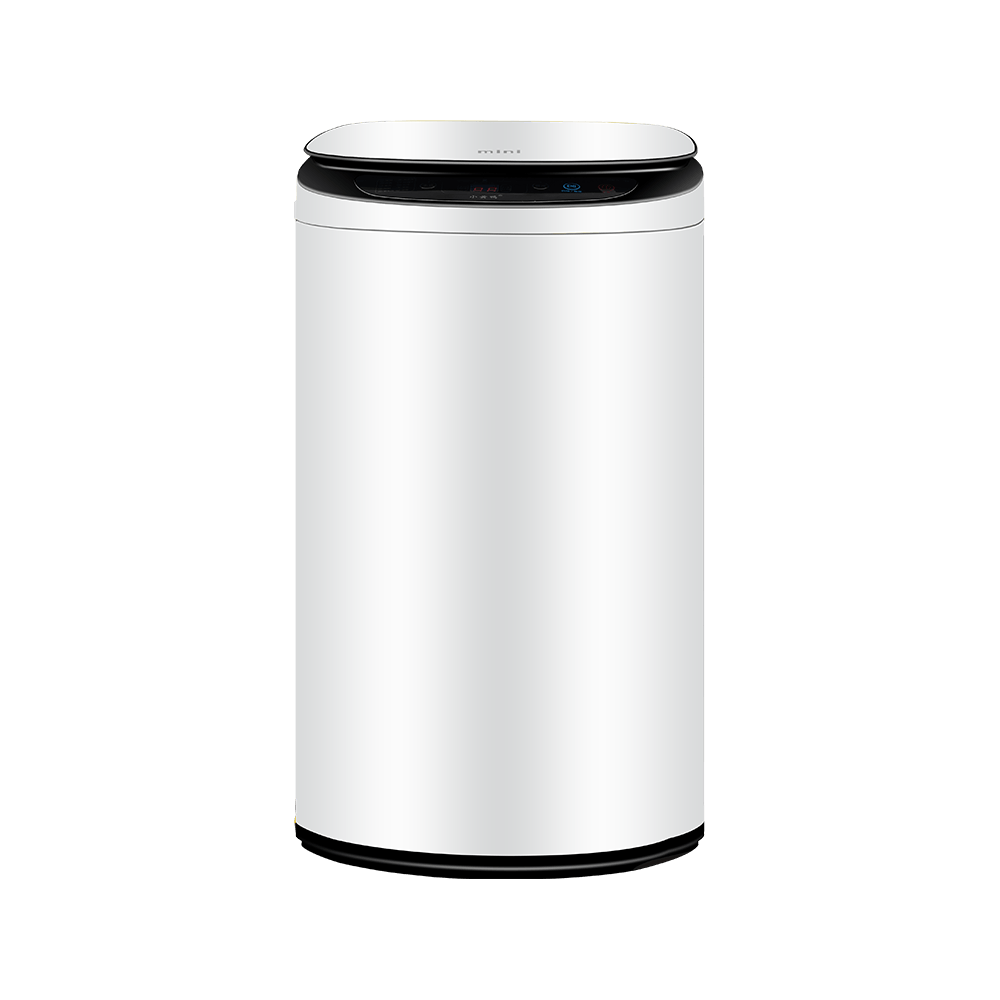

A fully automatic high-temperature pulsator washer is a type of cleaning machine designed to use a combination of high water temperature, pulsating action, and automation to effectively clean various surfaces and items. The high temperature helps to break down grease, dirt, and bacteria more efficiently, while the pulsating mechanism enhances the movement of the cleaning fluid, ensuring a more thorough cleaning process. The automatic function allows the washer to operate with minimal human intervention, streamlining the cleaning process and reducing labor costs.

In essence, these washers use a sophisticated system that controls the flow of water and detergent, adjusts temperatures, and automates the washing cycles. By precisely managing these variables, the washer can clean items faster and more efficiently, all while using less water and energy compared to traditional washing systems.

How the Pulsator System Contributes to Improved Cleaning Efficiency

The pulsator technology plays a key role in improving the cleaning efficiency of high-temperature washers. The pulsator generates a rapid, rhythmic movement of water and detergent that agitates the items being washed. This action creates a scrubbing effect that helps dislodge dirt, grease, and other contaminants more effectively than traditional methods, where cleaning relies primarily on mechanical or manual agitation.

When the pulsating water is combined with high temperatures, the cleaning power is further enhanced. The heat helps to break down stubborn stains and residues that may be difficult to remove at lower temperatures. This synergistic effect between heat and pulsation leads to faster and more thorough cleaning cycles, reducing the time needed for each wash.

Reducing Water Consumption with Efficient Washing Techniques

Water usage is a significant concern in many cleaning processes, especially in industries where large volumes of items need to be washed regularly. Traditional washing methods can consume large amounts of water, leading to higher operational costs and greater environmental impact. A fully automatic high-temperature pulsator washer, however, offers a more efficient approach to water use.

The automatic nature of these washers allows for precise control over the water flow, ensuring that only the necessary amount of water is used for each cycle. The pulsating action of the machine also helps to optimize water usage by ensuring that the detergent and water are evenly distributed and effectively penetrate all surfaces, reducing the need for excessive rinsing. This results in a significant reduction in water consumption without compromising the cleaning performance.

In addition, some models of high-temperature pulsator washers are equipped with water recycling systems that allow for the reuse of water from previous cycles. By filtering and treating the water, these washers can further reduce water waste and contribute to a more sustainable cleaning process. This feature is particularly beneficial in large-scale industrial applications, where water conservation is a priority.

Reducing Energy Consumption with Optimized Heating and Cycle Timing

Energy consumption is another key consideration when it comes to industrial cleaning processes. Traditional washers often require long cleaning cycles at high temperatures, which can lead to significant energy use. However, fully automatic high-temperature pulsator washers are designed to optimize both the heating process and cycle times, leading to reductions in energy consumption.

One of the main ways these washers reduce energy consumption is through their precise temperature control. By automatically adjusting the water temperature to the optimal level for each specific cleaning cycle, the washer avoids overheating the water, which would otherwise waste energy. This targeted approach to heating ensures that energy is used efficiently, without excessive power consumption.

Furthermore, the pulsating action helps to speed up the cleaning process, meaning that items can be cleaned in a shorter amount of time. By reducing cycle times, these washers reduce the amount of energy required per wash, further contributing to overall energy savings. This is especially important for industries that operate on a large scale, where small reductions in energy consumption can lead to significant savings over time.

Improved Cleaning Precision and Consistency

Another advantage of a fully automatic high-temperature pulsator washer is the ability to provide consistent cleaning results. In traditional washing systems, variability in operator technique, water flow, and temperature can lead to inconsistent cleaning outcomes. The fully automated nature of the pulsator washer eliminates this variability by ensuring that each cycle is completed with the same level of precision, every time.

This consistency is particularly important in industries that require strict hygiene standards, such as food processing or pharmaceuticals. In these sectors, even small residues or contaminants left on washed items can compromise product quality and safety. With a fully automatic pulsator washer, cleaning standards can be consistently maintained, helping to prevent cross-contamination and ensuring that all items are thoroughly cleaned.

Cost Savings through Increased Efficiency

One of the most significant benefits of using a fully automatic high-temperature pulsator washer is the potential for cost savings. By reducing water and energy consumption, businesses can lower their operational costs, which can be a major advantage in industries with high-volume washing requirements.

Additionally, the faster cleaning cycles and the reduction in manual labor associated with fully automatic washers further contribute to cost savings. With automation, fewer personnel are needed to oversee the washing process, allowing staff to focus on other tasks and increasing overall productivity. The faster turnaround times also mean that businesses can wash more items in a shorter amount of time, improving throughput and efficiency.

Although the initial investment in a fully automatic high-temperature pulsator washer may be higher than traditional washing equipment, the long-term savings in water, energy, and labor costs can provide a strong return on investment over time. Businesses that prioritize efficiency and sustainability are likely to see a positive financial impact from adopting this technology.

Environmental Benefits of Using High-Temperature Pulsator Washers

Environmental sustainability is an increasingly important consideration for businesses in all sectors. Reducing water and energy consumption is a key part of any sustainability strategy, and the fully automatic high-temperature pulsator washer offers significant environmental benefits in this regard. By optimizing water and energy use, these washers help to reduce the overall ecological footprint of the cleaning process.

In addition to reducing resource consumption, many high-temperature pulsator washers are designed with environmentally friendly materials and processes. For example, the water recycling systems mentioned earlier allow for the reuse of water, reducing the need for fresh water and minimizing wastewater output. This contributes to a more sustainable operation, particularly in industries with high-volume cleaning needs.

Furthermore, because these washers operate more efficiently, they help businesses reduce their carbon footprint by lowering the amount of energy required for each cleaning cycle. As energy consumption decreases, businesses can reduce their reliance on fossil fuels, contributing to a cleaner and more sustainable energy future.

English

English عربى

عربى