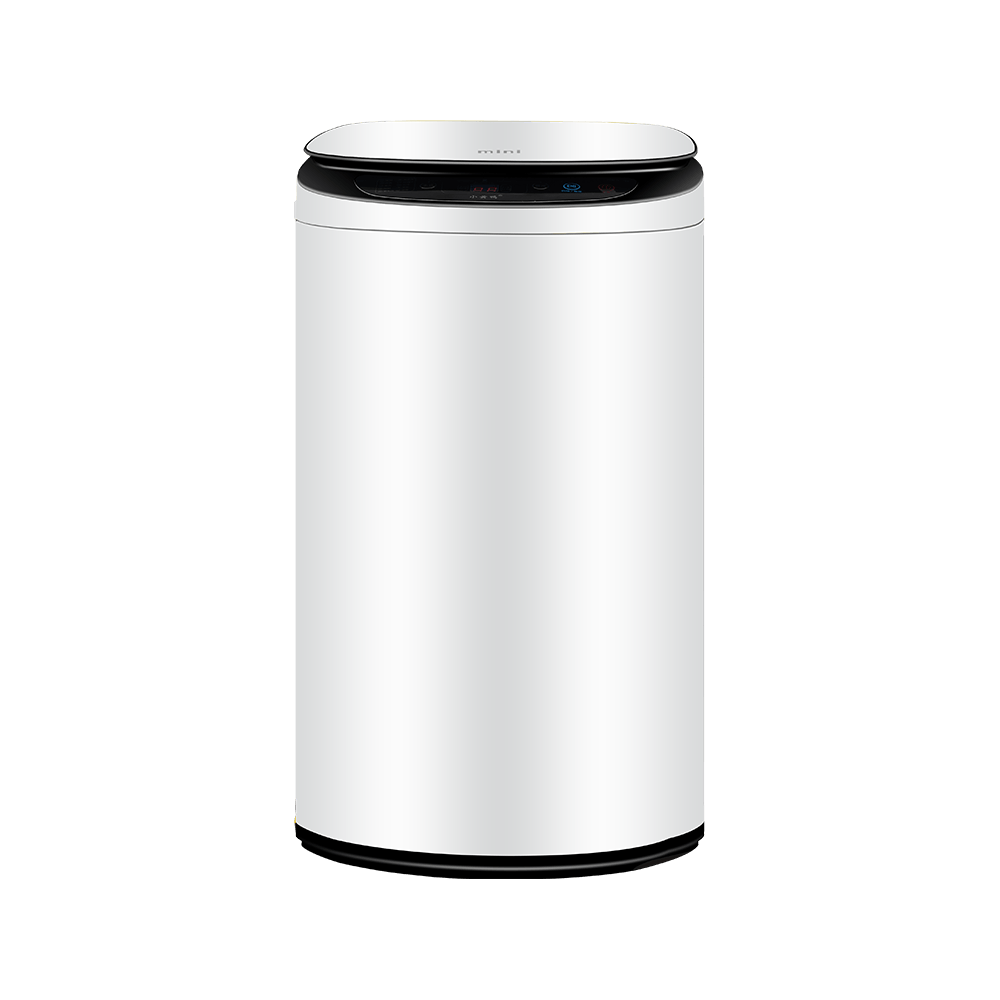

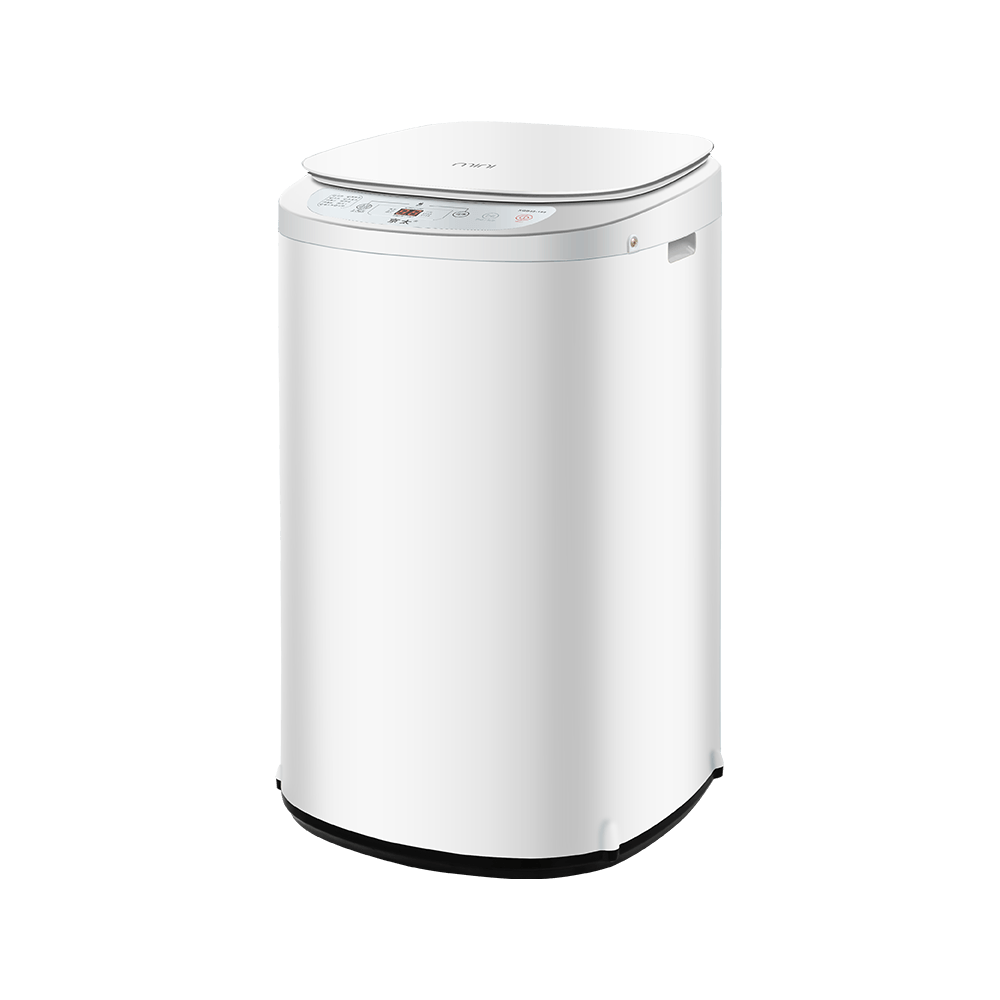

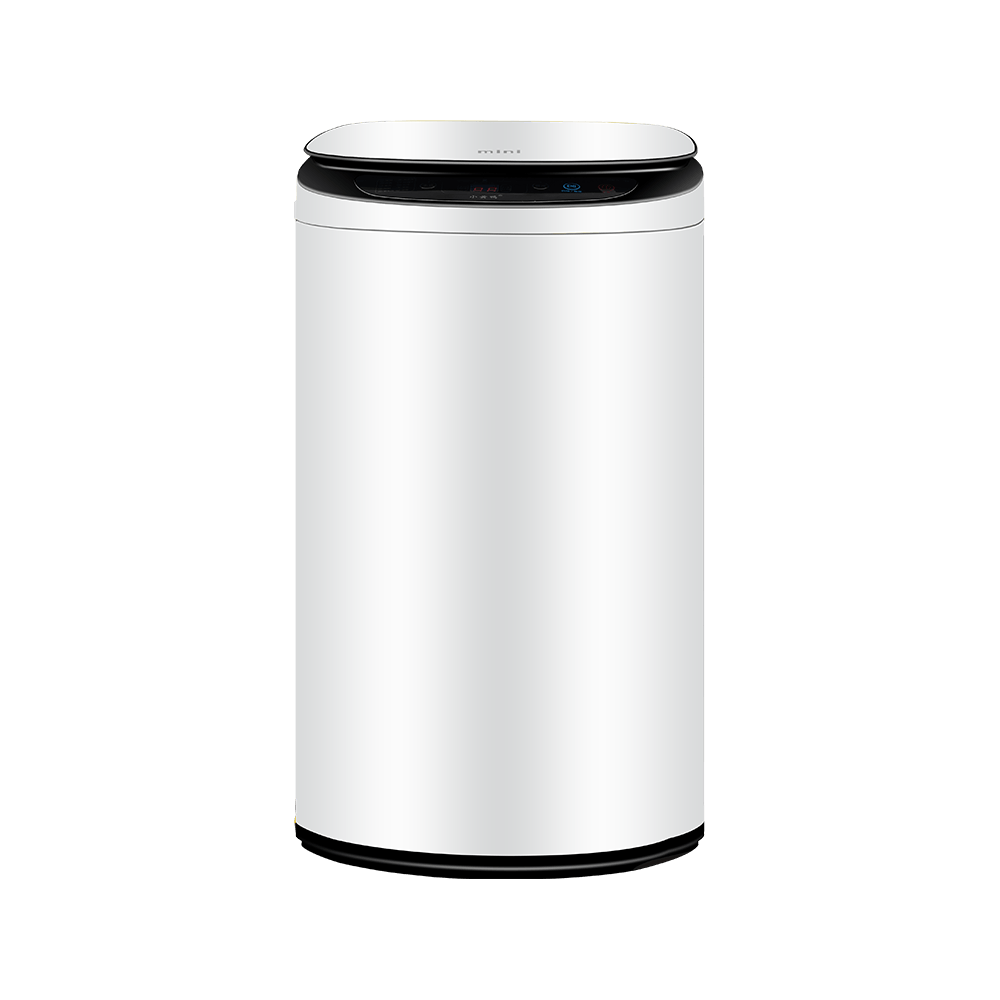

The top-loading door design is different from the drum-type side-opening door structure

The fully automatic blue light top-loading washing machine adopts a top-opening structural design, that is, the opening of the washing machine is located at the top. This structure is more suitable for an unobstructed environment above the washing machine in terms of spatial layout, which is convenient for users to stand and operate without bending over to take and put clothes. In contrast, the traditional drum-type washing machine has a side-opening door structure, which is suitable for embedded installation or placement under the washing table, but it requires bending or squatting when taking clothes, which is not convenient for some users. Therefore, in terms of ergonomic applications, the two structures have their own adaptation scenarios.

Blue light functional components are the core difference in the new structure

The blue light module is a more obvious structural addition in the fully automatic blue light top-loading washing machine, which is usually installed above the inner barrel or around the laundry detergent injection port. The module has a built-in LED blue light source, which usually acts as an antibacterial, deodorizing or auxiliary decomposition of washing residues. Compared with traditional washing machines, this functional component is not commonly equipped, so it is a new device in structure. The existence of this module makes the washing process not only limited to mechanical stirring and water washing, but also adds a cleaning method at the lighting level.

The inner drum structure mostly adopts a vertical impeller design

Blue-light top-loading washing machines are mostly equipped with impeller structures, that is, a rotating impeller disc is set at the bottom of the washing machine, which drives the water flow and clothes to stir through rotation. This structure is different from the horizontal drum structure used in traditional drum washing machines. The advantages of the impeller design are that the washing time is short, the water flow direction can be switched flexibly, and the clothes can be washed quickly. However, compared with the tumbling method of clothes in the drum structure, the stirring intensity of the impeller may cause greater friction on some soft fabrics. Therefore, there are significant differences between the two in terms of the structure affecting the washing method.

The automation control module is more integrated

The fully automatic blue-light top-loading washing machine is also different in the control system structure. It usually has a more integrated automatic control module built in, and users can select different washing programs through the panel or touch screen, including clothing material, water temperature, washing time, blue light exposure time, etc. This structural design is more digital than the traditional mechanical button washing machine, simplifies the operation process, and provides a more flexible function combination. The control module is usually concentrated in the control panel area on the upper part of the machine body, which is convenient for users to observe and operate.

The structure of the laundry detergent injection port is more diverse

The fully automatic Blue Light top-load washing machine is designed with a partitioned injection port for adding laundry detergent, softener or disinfectant, which is generally located in the groove under the cover. This injection port design takes into account the automatic delivery function and can automatically adjust the delivery amount according to the program. In contrast, the injection port of traditional washing machines is relatively simple, often requiring users to add manually, and does not have the ability to control the delivery amount. This structural improvement improves the convenience of operation and washing accuracy.

The arrangement of the filter and drainage system is different

The Blue Light top-load washing machine is generally equipped with a detachable filter on the edge of the inner barrel or the barrel wall to collect impurities such as clothing fibers and hair. This structure helps to keep the washing water clean and reduce the risk of drain pipe blockage. Traditional washing machines are also equipped with filtering devices, but the distribution location, capacity and cleaning methods are different. Some need to be taken out from the bottom of the machine body, which is not convenient to operate. The Blue Light top-load washing machine has improved the convenience of daily maintenance through structural optimization.

Transparent cover structure improves visibility

Some fully automatic blue light top-loading washing machines use transparent or translucent covers, allowing users to observe the status of clothes during the washing process and judge whether they are washed sufficiently. This structure is not common in traditional top-opening washing machines, and traditional products are mostly opaque covers. Adding a visual structure not only improves the user experience, but also makes it easier for users to stop the operation and make adjustments in special circumstances (such as clothes entanglement).

The whole machine shell material and waterproof design are more practical

Fully automatic blue light top-loading washing machines usually use rust-proof metal or engineering plastic materials as the shell, and some models are coated with anti-fingerprint and waterproof coatings. This type of structural selection helps to improve the stability of washing machines in humid environments. Although traditional washing machines also have a variety of material options, they differ from new blue light products in terms of structural sealing and splashproof levels.

Self-cleaning function structure integrated into the inner barrel and pipeline system

Blue light top-loading washing machines are usually equipped with barrel self-cleaning or blue light auxiliary cleaning programs. Its structure reserves cleaning water flow channels in the drainage pipe and the inner barrel part, and some models also have separate self-cleaning program buttons. Compared with traditional washing machines, this structure makes it easier for users to remove the residue in the barrel without using professional detergents, keeping the washing environment relatively clean.

The overall structure focuses more on user convenience and maintenance efficiency

The fully automatic blue light top-loading washing machine is more centralized and modular in terms of operation interface, function settings, maintenance methods, etc. Users can complete settings, observations and detergent additions at the top, reducing the need to bend over and repeat operations. Although traditional washing machines are functional and practical, they are slightly scattered in terms of humanized structural design. Operations in different parts need to be switched back and forth, which some users may find inconvenient in long-term use.

English

English عربى

عربى