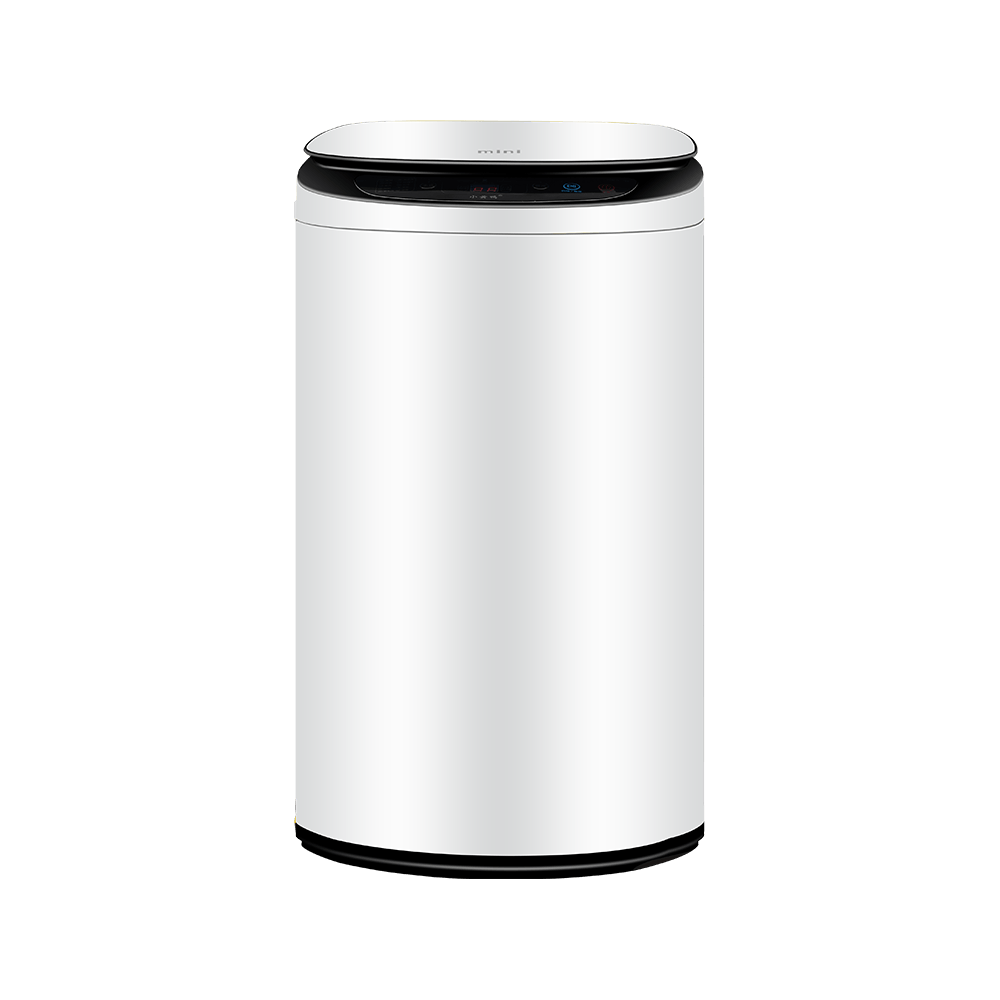

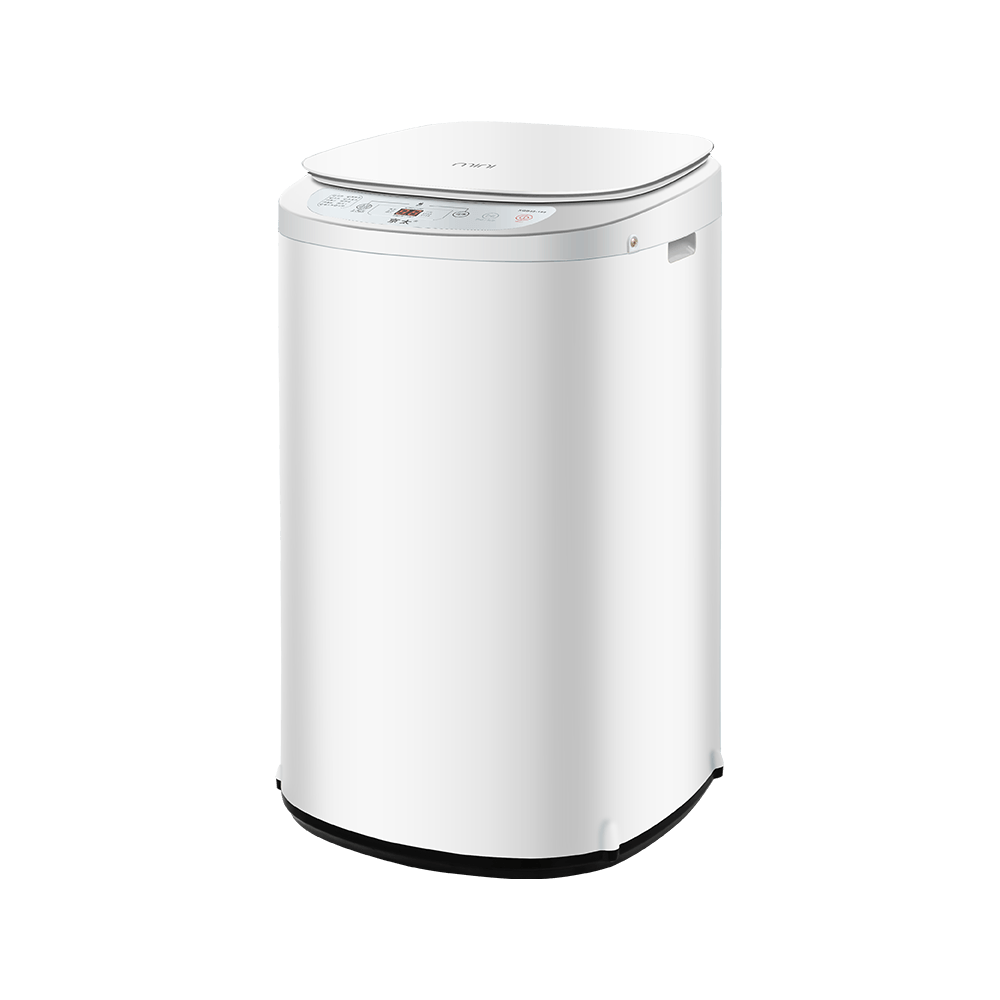

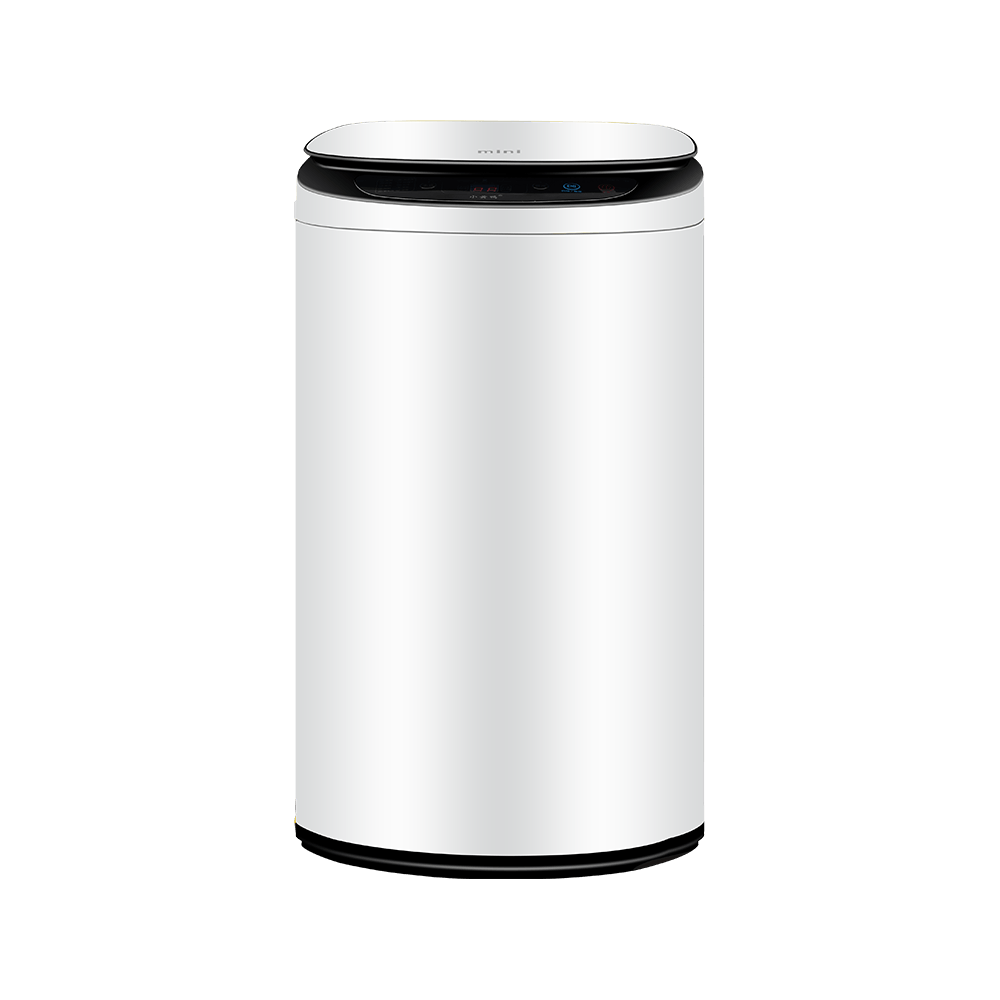

Automatic Water Level Control

Fully automatic blue light washing machines are designed to adjust water levels based on the weight and type of laundry. Sensors embedded in the drum detect the load size and water absorption characteristics of fabrics, allowing the machine to fill with the appropriate amount of water for each cycle. This automatic water level control prevents overfilling, which could lead to spillage or inefficient washing, and underfilling, which could reduce cleaning effectiveness. By regulating water levels precisely, the washing machine ensures optimal performance while maintaining safety for both the appliance and the surrounding environment.

Detergent Dosage Control

Detergent dosage is another critical factor in fully automatic blue light washing machines. Modern machines include compartments and dispensing systems that release detergent according to the load size, fabric type, and selected washing program. Sensors measure the amount of detergent dispensed to ensure it aligns with the washing requirements, preventing excessive chemical exposure or residue buildup. Proper detergent dosage contributes to user safety by reducing skin irritation risks and minimizes environmental impact by avoiding unnecessary chemical discharge. Automatic control also improves washing efficiency and protects machine components from detergent-related damage.

Safety Mechanisms and Features

Safety is a key consideration in fully automatic blue light washing machines. Automatic water level control prevents overflow and reduces the risk of electrical hazards caused by water spillage. Detergent dosage control prevents excessive suds that could cause leaks or malfunction. Additionally, built-in sensors monitor door locking, water temperature, and drum rotation speed to prevent accidents during operation. Overload protection ensures the drum does not spin under excessive weight, and automatic shut-off mechanisms activate if abnormal conditions are detected. These combined features make the washing machine safer to operate in domestic settings.

Technology Behind Blue Light Features

The blue light in these washing machines often serves multiple purposes, including hygiene enhancement and operational safety. Blue light may act as an indicator for correct detergent and water levels or as an antibacterial measure in some models. The integration of blue light technology with automatic control systems allows the machine to optimize water and detergent use while maintaining safe operation. Sensors linked to the lighting system can provide visual feedback to the user about the machine’s current status, helping to prevent misuse and ensure that washing cycles are completed safely and effectively.

Maintenance and Sensor Calibration

Regular maintenance and sensor calibration are essential for fully automatic blue light washing machines to continue controlling water and detergent accurately. Over time, sensors may become less responsive due to detergent residue, mineral buildup, or mechanical wear. Routine cleaning of the detergent compartment, water inlet filters, and drum helps maintain accurate sensor readings. Manufacturers often recommend periodic checks and recalibration to ensure the machine continues to dispense the correct amount of water and detergent. Proper maintenance extends the machine’s lifespan and ensures continued safety during use.

Comparative Table of Key Features

| Feature |

Description |

Safety Impact |

| Water Level Control |

Sensors detect load weight and fabric type to fill appropriate water volume |

Prevents overflow, reduces electrical hazards, optimizes cleaning efficiency |

| Detergent Dosage |

Automatic dispensing based on load and program selection |

Prevents chemical overexposure, reduces skin irritation, avoids residue buildup |

| Blue Light Indicators |

Visual feedback on operation status and hygiene functions |

Helps prevent misuse, confirms correct cycle operation, supports antibacterial measures |

| Overload Protection |

Prevents drum from spinning when overloaded |

Protects machine components and reduces risk of mechanical failure |

| Automatic Shut-Off |

Activates under abnormal conditions such as water leakage or sensor error |

Reduces risk of accidents and ensures user safety |

Energy and Water Efficiency

Automatic water and detergent control not only enhances safety but also improves energy and water efficiency. By filling only the necessary amount of water and dispensing the precise detergent dosage, fully automatic blue light washing machines reduce waste. This optimization minimizes energy consumption for heating water and operating the drum, contributing to environmental sustainability. Users benefit from lower utility bills and a reduced ecological footprint while maintaining safe washing practices. Efficiency and safety are therefore interconnected in the design of these machines.

User Interaction and Guidance

Modern fully automatic blue light washing machines provide guidance to users through intuitive interfaces, often linked to the automatic water and detergent control systems. Display panels or blue light indicators inform users when the detergent compartment is correctly filled and whether the load is within safe weight limits. Some machines include error messages or alerts if sensors detect anomalies, preventing unsafe operation. Clear feedback and user guidance ensure that even those unfamiliar with the technology can operate the washing machine safely and efficiently.

Integration with Smart Features

Many fully automatic blue light washing machines now integrate with smart home systems or mobile applications. These connections allow users to monitor water and detergent usage remotely, receive alerts about maintenance requirements, and track the washing cycle status. Smart sensors communicate with the control system to automatically adjust water levels and detergent dosage in response to variations in load or fabric type. This integration enhances operational safety by reducing human error and providing real-time feedback on machine performance, while also supporting energy and water conservation.

Material Durability and Chemical Resistance

The internal components of fully automatic blue light washing machines are made from durable, corrosion-resistant materials to withstand repeated exposure to water and detergents. Pumps, hoses, and drum assemblies use plastics or stainless steel that resist chemical breakdown and maintain structural integrity over time. Durable materials help ensure that automatic water level and detergent control systems continue to function accurately, even after thousands of washing cycles. This durability is essential for maintaining both the safety and performance of the appliance throughout its service life.

English

English عربى

عربى